Drum filling solutions

With a legacy spanning over 30 years, PACK’R Filling Specialists has been manufacturing drum filling solutions dedicated to the packaging of liquid products based on the most advanced weight filling technologies.

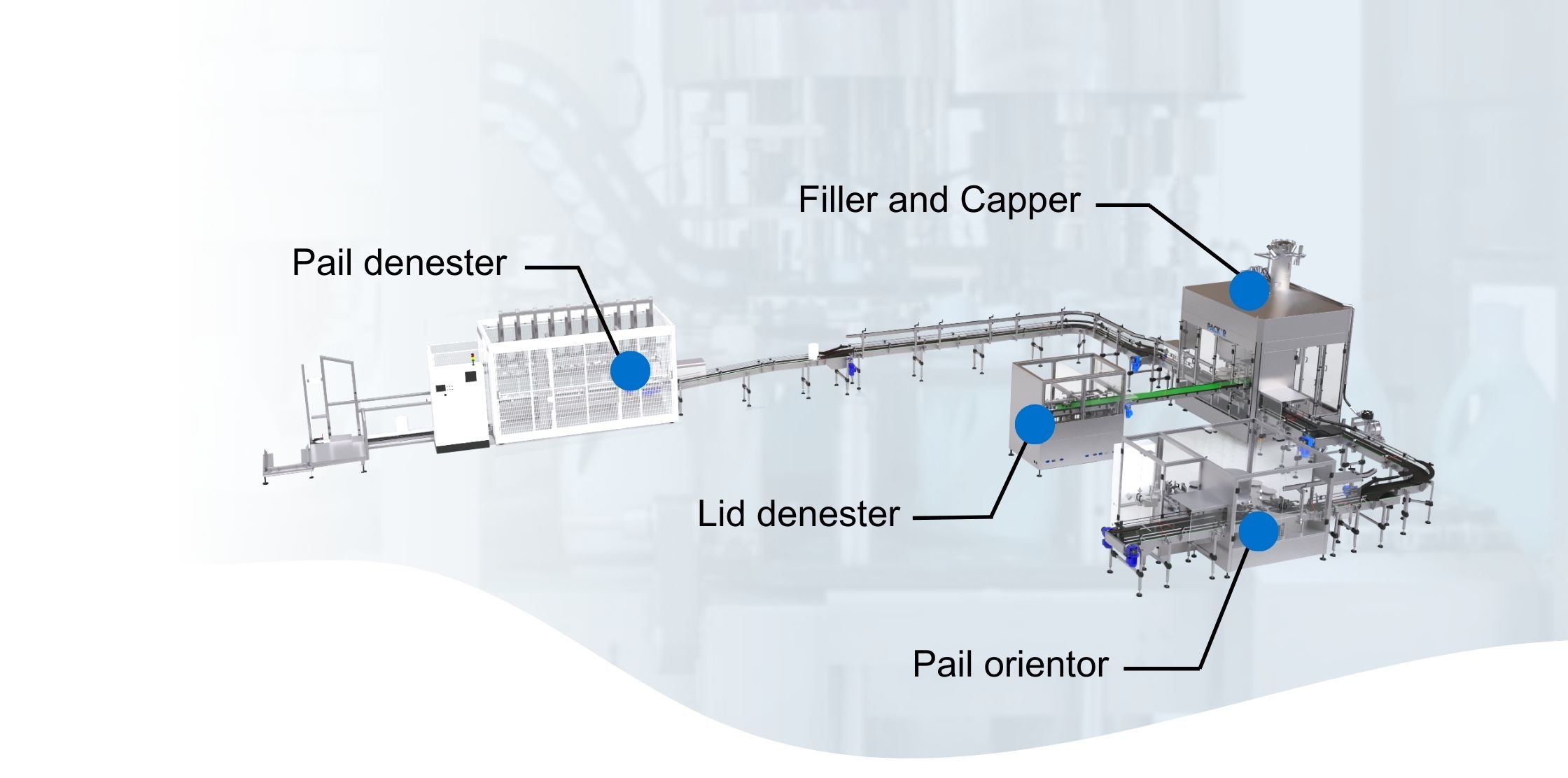

Flexibility often being key to success, our semi-automated and fully automated filling machines can fill a wide range of products into various containers. Additionally, PACK’R fillers can be equipped with a capping function that can effectively manage different types of caps.

Why Choose PACK’R for your Drum Filling Equipment?

Benefits of Our Drum Filling Solution

- Unmatched Precision: Every drop counts. Our weight fillings technologies ensure the most precise measurement for optimal dosing.

- Operational Efficiency: Save time and increase productivity with our advanced drum filling equipment.

- Customized Flexibility: We understand that every industry has unique needs. Our team works with you to customize solutions according to your requirements.

- Commitment to Sustainability: We are committed to reduce our environmental impact.

Cutting-Edge Technologies

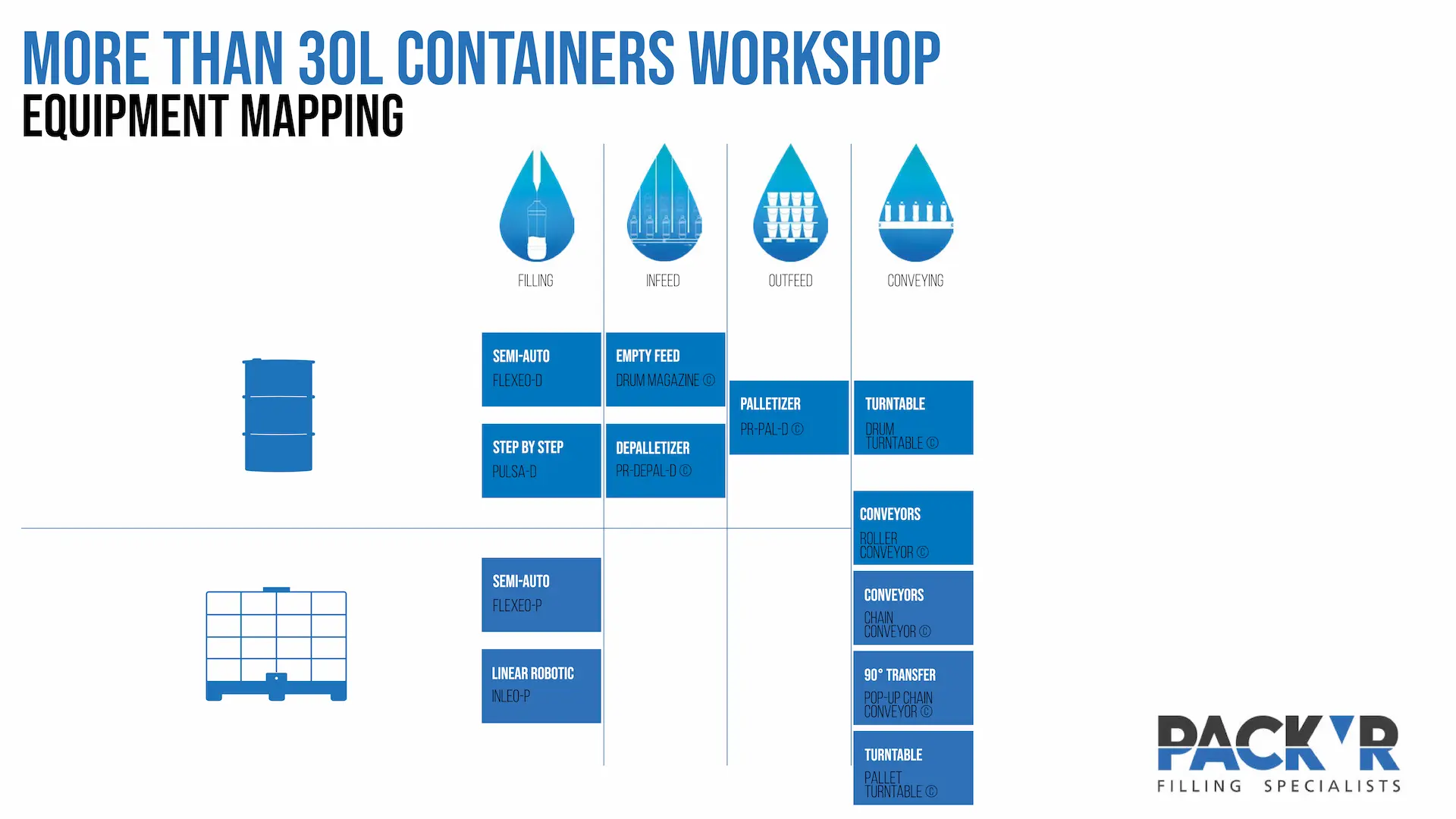

PACK’R offers a wide range of solutions according to your production needs, from small production batch with our semi-automatic systems to large series with automatic drum filling machines. At PACK’R, we know that handling drum is not easy. Also we developed two ranges of systems able to fill drum-by-drum (at speeds up to 120 drums per hour) or drums on pallets and standalone IBC totes (at speeds up to 12 per hour). Product compatibility playing a crucial role in packaging, all our machines can be available with materials in contact with products in stainless steel or plastic.

Our filling machines also have a capping function for drums (2″ bung) as well as a tab seal applicator function (metal crimped tab seal or plastic press-on over cap).

Our systems can be designed to:

- Handle hazardous, toxic, corrosive, foaming, explosive products…

- Operate in flammable environment as per ExProof/ATEX guidances.

- Enable incompatible products to be packaged in the same machine (dedicated product lines).

- Allows packaging of a wide range of viscosities (3″ filling lance).

- Provide an effective, hermetically sealed cleaning solution with the use of a cleaning collector.

- Ensure the safety of operators, while considering the environment and conditions in which the installation will be located.

Our markets

We have more than 1300 filling machines and packaging lines installed in the world combining innovation and new technologies. We have developed a specific know-how recognized worldwide in the filling of complex liquids.

Some of our installations are producing for over 30 years, with an average life-time of 20 years. This shows the quality and longevity of our solutions.

Agrochemicals

Chemicals

Paint

Petrochemicals

Vegetable oils

Food

ATEX- Explosion proof expertise

Over the years, PACK’R has manufactured numerous machines and has developed a real expertise in ATEX – Explosion Proof (ExProof) design, in particular to meet the problems of our customers’ markets and products: solvents, flammable petroleum products, hazardous products, solvent-based paints, beverage concentrates, etc. We design and manufacture simple semi-automatic machines for hazardous locations as well as automatic filling and capping machines, up to the complete line in ATEX/ExProof design.

You have a project or need information ?

A dynamic companyin constant search of innovation

Prestigious clients, leaders in their domain

An R&D office at the cutting edge of technology

Filling of your complex liquid products

Subsidiaries in Asia and North America