Select the liquid filler adapted to your needs

Bottles

PACK’R is specialized in the design and manufacture of filling and capping machines dedicated to the packaging of liquid and viscous products. Our weight fillers can adapt to different types of packaging from 100ml to 1000L: bottles, jerrycans, jars, buckets, barrels, IBCs…

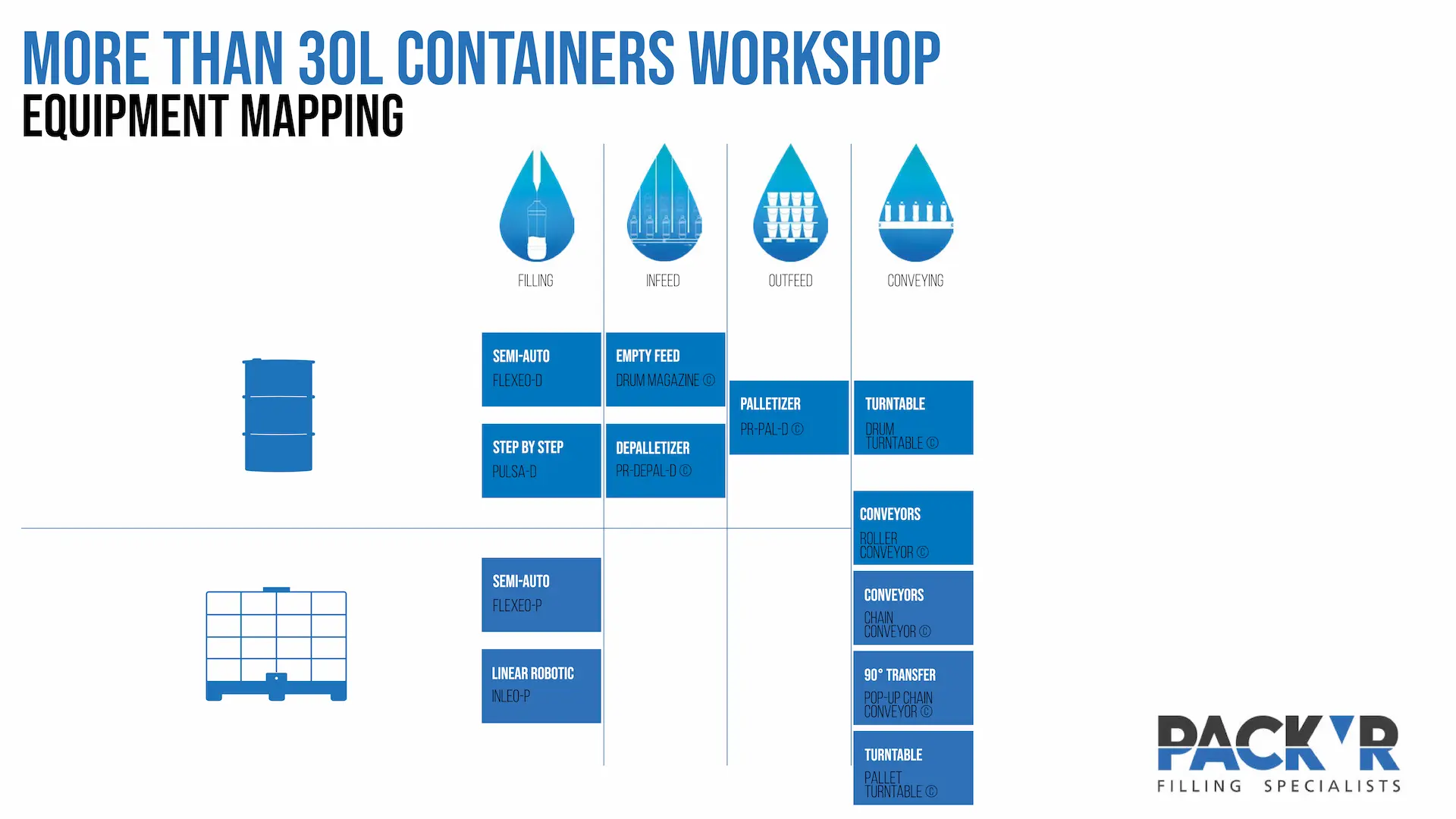

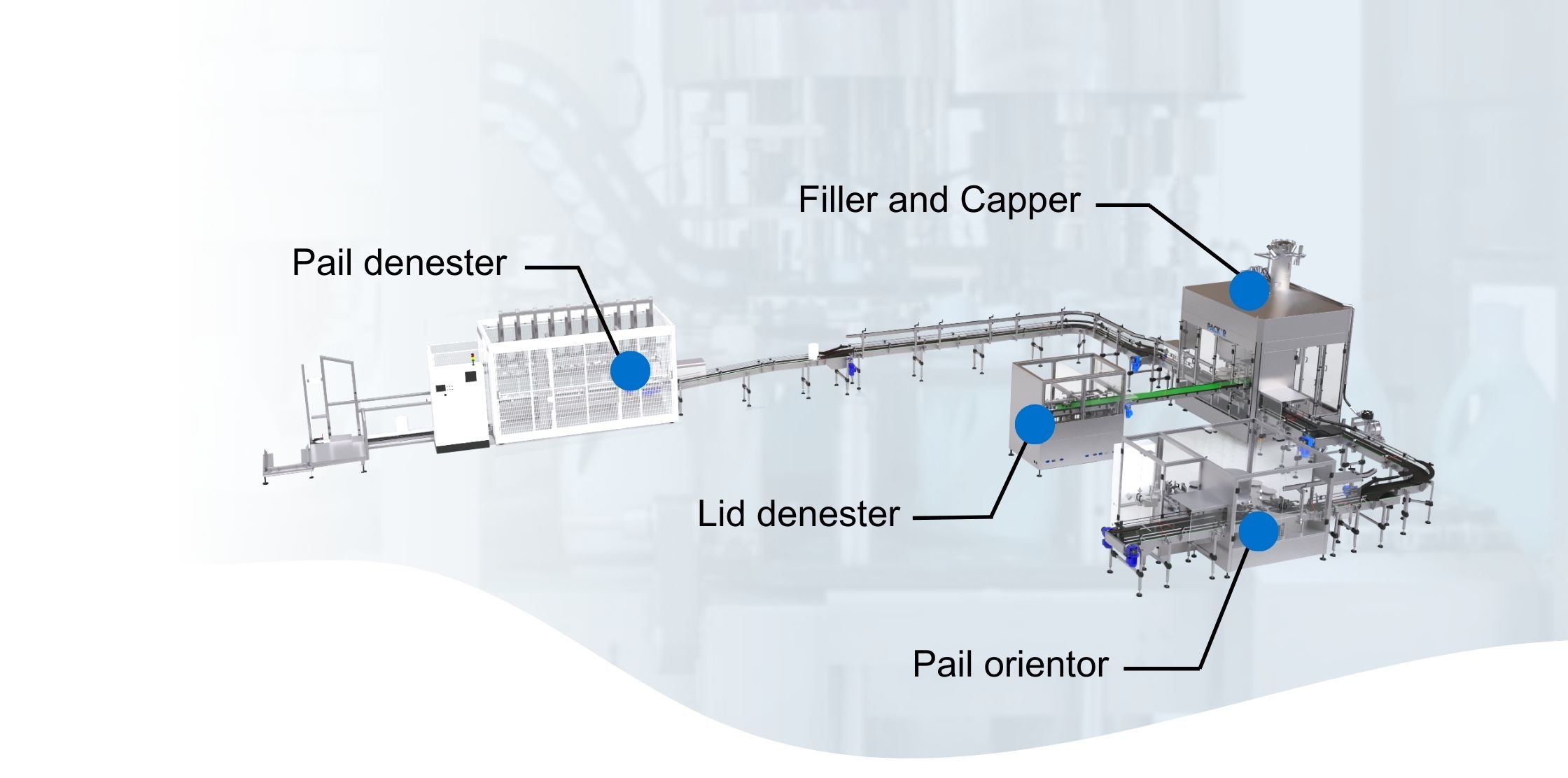

We have a wide range of machines at our disposal: from standard “turnkey” dosing machines to complete lines. Our catalog is completed with various equipment: palletizers, depalletizers, canister denester, bucket / lid denester… Our engineering teams will accompany you throughout your project: from the study of your request and your specifications, then throughout the realization and throughout the life of your machine thanks to our maintenance and training services. Our experts put their know-how and advice at your service to offer you adapted solutions.

We have more than 1300 machines and packaging lines installed in the world combining innovation and new technologies. We have developed a specific know-how recognized worldwide for more than 30 years in the filling of complex liquids.

The right technology for your liquid filling machine

To ensure safe, efficient, and precise operations, we’ve developed specialised technologies that prioritise both operator safety and product integrity:

-

Closed-cabin machine range for enhanced containment

-

Corrosion-resistant construction using materials such as PP, PE, and others

-

Net weight filling for the best dosing accuracy and improved end-of-batch control

-

Pressurised tanks for consistent product flow

-

Integrated fume extraction systems

-

Advanced anti-drip mechanisms to maintain clean filling environments

-

Torque-controlled capping using magnetic or brushless systems

-

Nitrogen purging before and during capping for added protection

-

Patented cleaning solutions that significantly reduce wastewater volumes

-

Data export options for enhanced traceability and production monitoring

Our strength lies in our deep technical know-how and continuous innovation. With extensive experience in ATEX-certified environments, our solutions are engineered to meet the strictest industrial standards and the most demanding customer specifications.