Pail filling machine for liquids

For more than 30 years, PACK’R has been designing machines to fill pails from 500mL to 30L, using the most advanced weight filling technologies for greater accuracy. From semi-automatic to fully automatic pail filling machine, they can adapt to different shapes and materials. PACK’R fillers also include a capping function capable of handling a wide variety of lids.

Our range of pail filling machines can be adapted to your packaging, your targeted output and your products (Chemicals, Agrochemicals, Petrochemicals, Paint, Vegetable oils and certain food products).

Our goal is to provide you with the pail filling machine that perfectly meets your requirements.

Cutting-edge Technologies for Your Pail Filling Machine

We design and manufacture your pail filling system using weight dosing technology to ensure the best possible accuracy, regardless of aeration, temperature or product viscosity. As a result, the initial investment pays for itself more quickly by avoiding over-dosing.

We offer a variety of pail filling machines to meet your production needs, from small production runs with semi-automatic systems to large-scale production runs with medium and high-speed automatic solutions.

Our filling machines can be adapted to different materials: plastics (HDPE or PP) and metal. They also have a closing function that can be adapted to several types of lids: push-on plastic, crimp-on metal, pre-orientated lids, etc. Our patented changeover system, with tool-free operation, makes it easy to change from one container size to another.

With our latest R&D solutions, our high-speed machines can be compatible with intensive changeover thanks to :

- Fill & Clean Technology : cleaning and filling operations performed at the same time by combining 2 product lines into the same machine.

- Flex & Play Technology : no tool replacement during changeover. Adjustments only and performed within seconds.

Our developments and technologies are designed to:

- Handle hazardous, toxic, corrosive, foaming and explosive products, etc.

- Operate in ATEX environments.

- Enable packaging of a wide range of viscosities: pressurised filling solution possible.

- Provide efficient cleaning solutions. Reduce your washing time and effluent volume thanks to our patented automatic connection with recirculation loop, back flush and other features.

- Ensure operators safety, while considering the environment and the conditions in which the installation will be located.

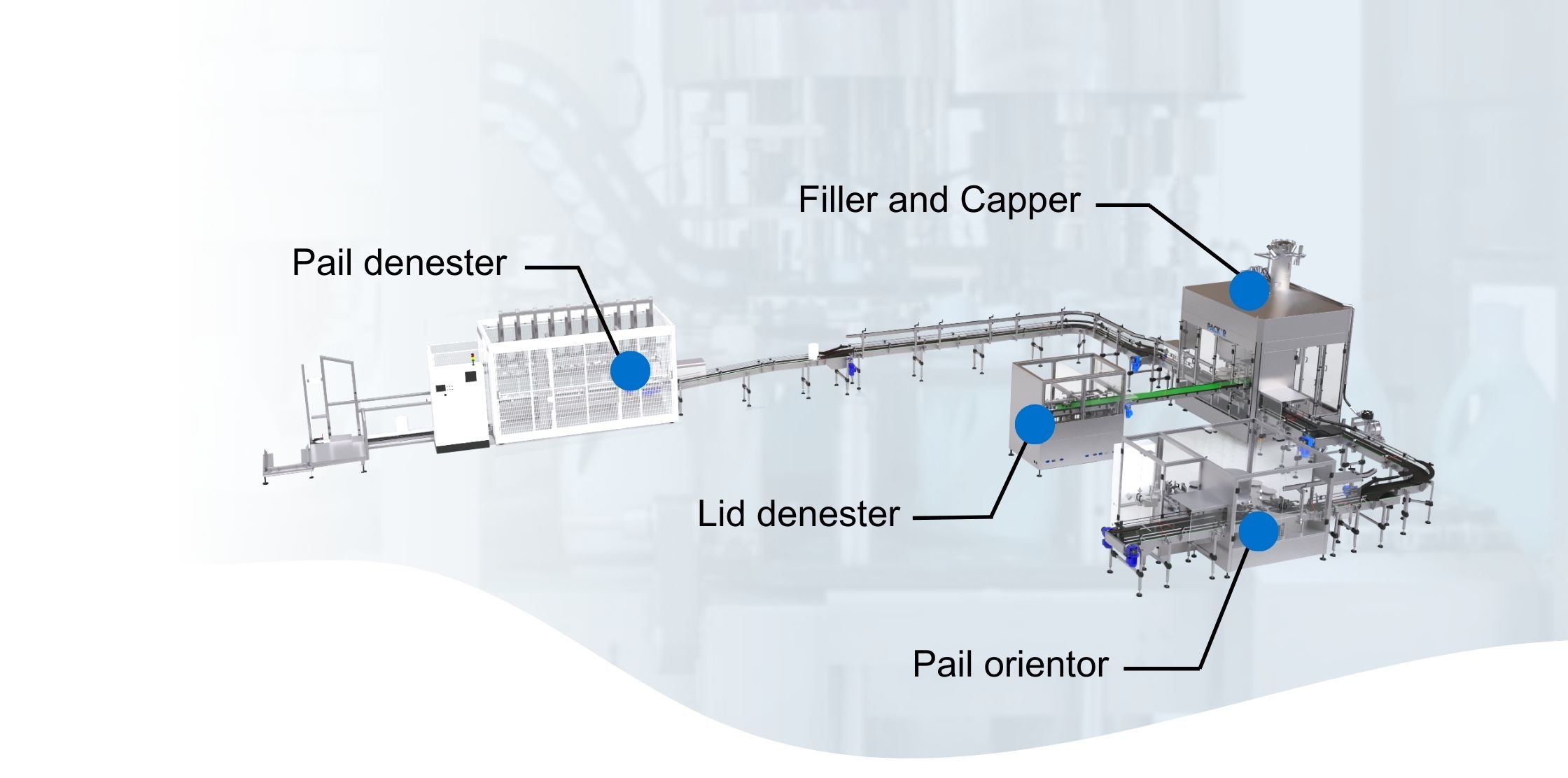

To complete our machines range, we have a number of additional solutions:

- For feeding empty buckets by denesting: up to 30 containers per minute (20 litres)

- For feeding lids by denesting (up to 120 containers per minute)

- A labeller for stickers or barcodes with pail orientator: up to 40 containers per minute (20 litres).

Some of our installations are producing for over 30 years, with an average life-time of 20 years, proof of the quality and longevity of our solutions. See also our filling machines for other containers type : Bottles, Jerry cans, Drums / IBC.

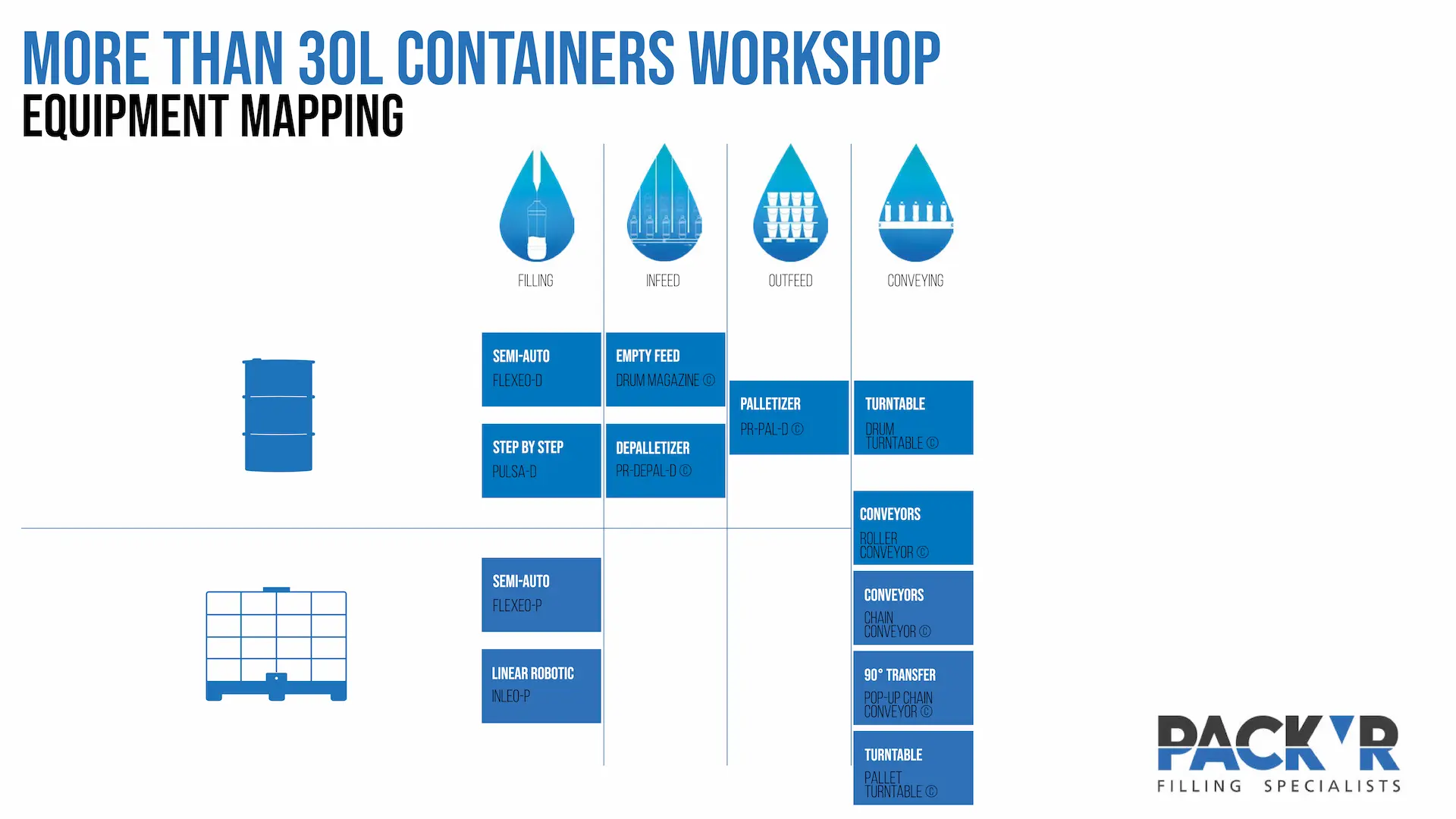

Select your liquid pail filler according to your market