Drum on Pallet and IBC Filling Machines

As a global specialist in liquid filling technologies, PACK’R designs high-performance drum-on-pallet and IBC filling and capping machines engineered to deliver accuracy, safety, and durability for every industrial environment. With more than 30 years of expertise, we provide advanced systems dedicated to Intermediate Bulk Containers (IBCs) and totes. We serve chemical, agrochemical, petrochemical, food, paint, edible oil and liquid concentrate.

Our IBC filling machines maintain production consistency with large-volume containers while combining high-speed filling and precise dosing control, ensuring maximum productivity on your bulk packaging line.

Engineered for Complex Liquid Filling

Modern production demands process flexibility and reliability. PACK’R IBC filling and capping systems are designed to handle a wide variety of products:

- Chemical solvents

- Viscous sauce without particles

- Concentrated corrosive liquids

- Foaming or temperature-sensitive liquids

To meet these diverse requirements, we offer versatile dosing technologies:

- Net-weight filling for the highest precision and the minimum giveaway

- 3″ filling lance for high speed production that reduce foaming, dripping, and product loss

Safety Built Into Every System

Whether your industry prioritizes hygiene or hazardous-area safety, PACK’R ensures full compliance with international standards.

- ATEX-compatible design for explosive atmospheres

- Works directly on the pallet, reducing container handling and contamination

- Stainless steel construction available for all product-contact parts

- Optional automatic CIP nozzle cleaning system

- Gentle and safe container handling

Select your IBC and drum filler according to your market

Chemicals

Key Features of PACK’R IBC Filling Machines

- Large range of pallet filling machine

From flexible semi-automatic stations to high speed fully automated lines there is a machine according to your production needs - Precision Dosing & Clean Filling

High-speed, anti-drip valves ensure clean fills even with foaming or viscous liquids. - Multi-Container Capability

Smooth changeover between filling IBCs, totes, drums, or palletized groups of containers on pallet - Integrated CIP Systems

Clean-In-Place solutions with hermetic collection systems protect both the operator and the environment and limit the contact with hazardous liquids - Easy Handling for operators

Ergonomic nozzle positioning, automated lifting, and safe positioning supports improve workflow efficiency.

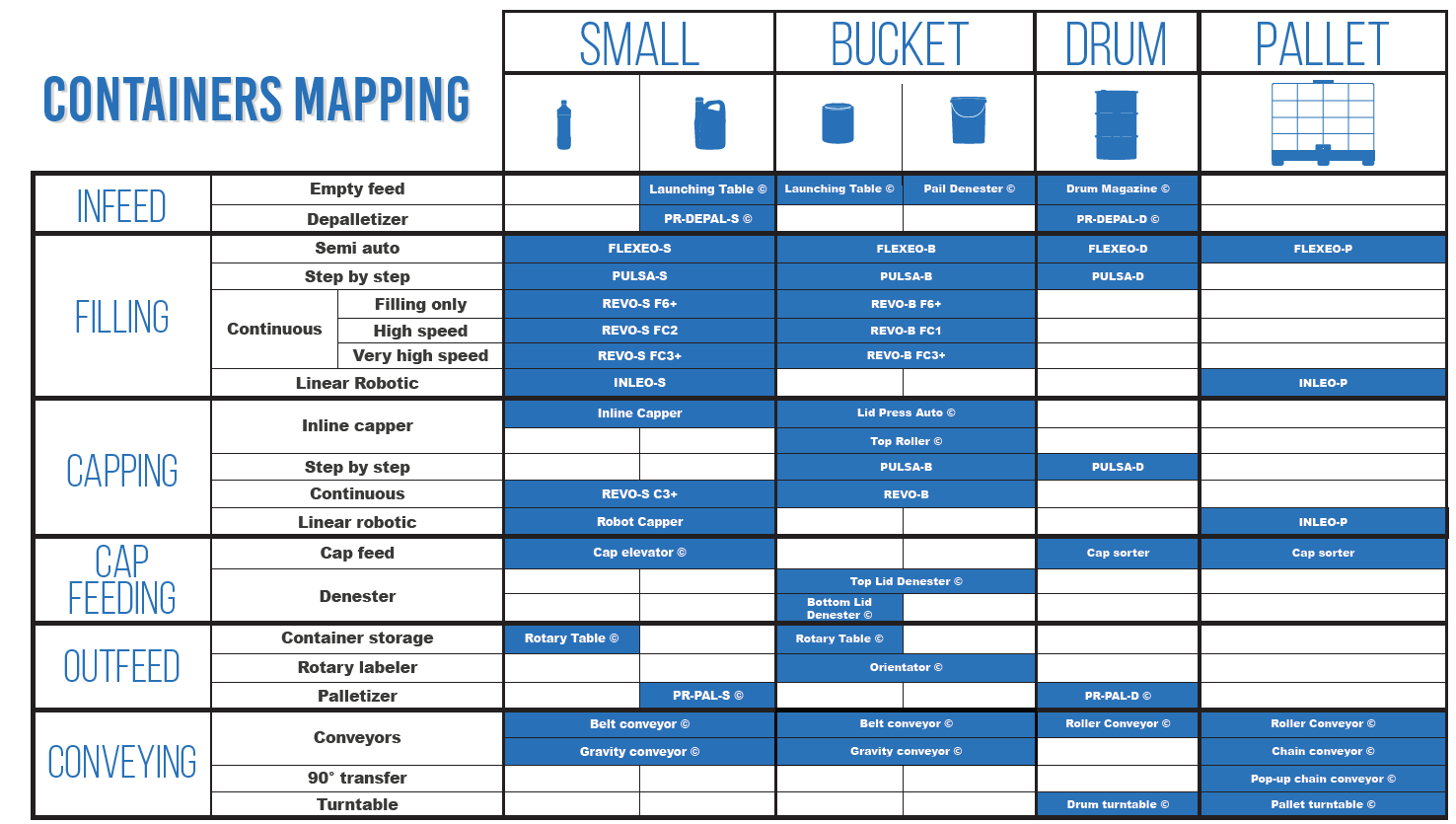

Complete Line Integration for Liquid Packaging

To optimize your packaging process, PACK’R provides a full ecosystem of additional equipment, including:

- Pallet conveyors

- Infeed systems like palletizer or drum magazine

- Capping machine integrated in the line or in the filler

- Automatic control stations

- Vision and traceability solutions

With more than 1,400 installations worldwide, PACK’R supports you from project design and container handling strategy to installation, commissioning, and long-term service. Our global technical team ensures that your drum on pallet or IBC filling machine continues to perform at its highest level during all its lifecycle.

Choose PACK’R for Your Next IBC Filling Machine

Whether you need a semi-automatic filler for smaller batches or a fully automated IBC filling and capping line for high-throughput production, PACK’R delivers reliability, accuracy, and long-term value. Our machines are engineered to evolve with your process making them a strategic investment for any industrial liquid packaging environment.